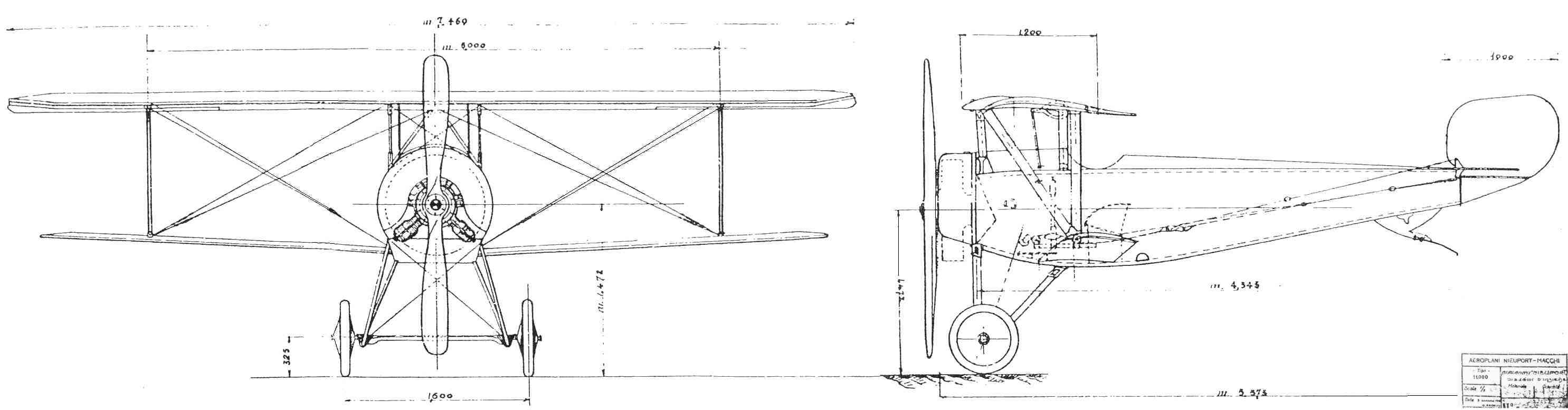

• Building a Nieuport 11 replica •

The original Nieuport clearly had issues with the tailskid arrangement as a number of machines were modified and later models had a revised arrangement.

It also appears that many replicas have ended up tail heavy.

The challenge was therefore to create a strong tailskid arrangement that was as light as possible.

As I was intending to operate off grass and would have differential brakes I decided not to install a tailwheel but to retain the original tailskid arrangement.

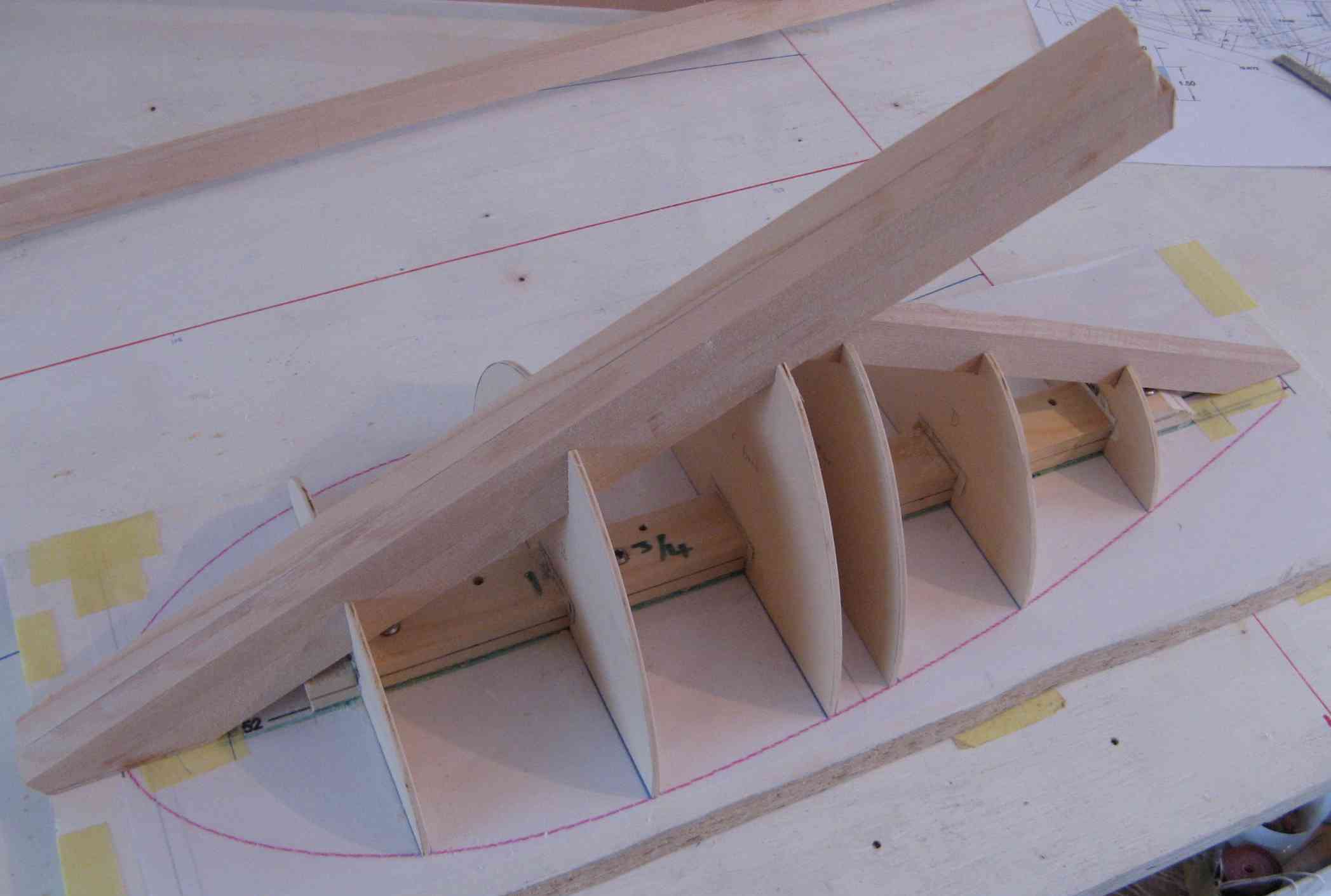

The tailskid is supported by a fairing. On the original aircraft this was timber, but I decided to create a timber frame with kevlar covering.

The frame comprised simple ply bulkheads. The central bulkhead is reinforced with spruce within a balsa core.

The kevlar fairing would be laminated within a female mold.

Stage one was therefore the construction of a male plug, carved out of florists foam.

The male mold is waxed and then covered with plaster of Paris using pre-impregnated plaster bandages.

Layers are built up to give sufficient strength.

Once the female mold is finished and dried it is waxed and the kevlar layers are laminated up.

WEST system expoxy is used for this task, rather than T-88 adhesive, as it is thinner and more suited to fibreglass lamination.

The kevlar is cut and trimmed using special scissors. Ech layer is carefully trimmed before the glue dries as cutting the kevlar once set is nigh impossible.

Once the kevlar fairing is finished the timber framework is inserted.

The main bulkhead is attached to the fuselage with brackets. These have anchor nuts attached as the bracket will be inside the fairing.

The finished tailskid and fairing after painting and varnishing.

The kevlar skid is not yet attached.

The parts for the wheel hub, flanges and brake arm.

The flanges and brake arm parts will be brazed together.

The completed metal parts for the hub and brakes.

Wheel hubs, brake rotors, spacers, brake arm and bronze bearings.

The undercarriage being assembled.

The axle shown is just a dummy length of aluminium tube.

The actual axle is 1.25" OD steel tube and sits at the bottom of the slot (shown at top of picture).

It is held in place by three wrappings of 3/8" bungee cord. The timber at the base of the undercarriage (shown at top) will have smooth slots cut to guide the bungee.

1/8" cross wires have yet to be fitted.

The wheel being laced.

Coloured straws are used to identify the different spoke groups. This allows the spokes to move sufficiently to insert the spokes and also makes it easier to check that the spoke layout is correct.

The rim is from a Honda C90 cub. The spokes are custom made.

The hub has been fabricated based upon the system used by Pietenpol builders and documented on their website.

The final wheel.

Total weight of each wheel is 5.05kg.

The coloured dot on the tyre should be next to the valve. In addition there is a direction arrow on each tyre which should match the direction of rotation.